Wire EDM

The machinists at Hardy-Reed are experts in Wire EDM & EDM Hole Drilling Services

We are an industry leading EDM company. We have decades of experience in this specialized field. Hardy-Reed is one of the most accurate and most efficient wire cut EDM manufacturers in the industry. We provide both wire EDM machining and EDM hole drilling services. Hardy-Reed has state-of-the-art, CNC-operated production equipment to create precision parts and components that match your design specifications.

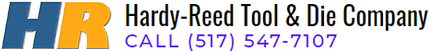

Electrical Discharge Machining

An electrical spark is created between an electrode and a work piece. The spark is visible evidence of the electricity flow. The spark produces intense heat with temperatures reaching 8,000-12,000 degrees Celsius, melting almost anything. The spark is carefully controlled and localized so that it only affects the surface of the target material. The EDM process normally doesn’t affect the heat treat below the surface. The spark takes place in the dielectric of deionized water. The conductivity of the water is controlled, making it an excellent environment for the EDM process. Water acts as a coolant and flushes away eroded metal particles.

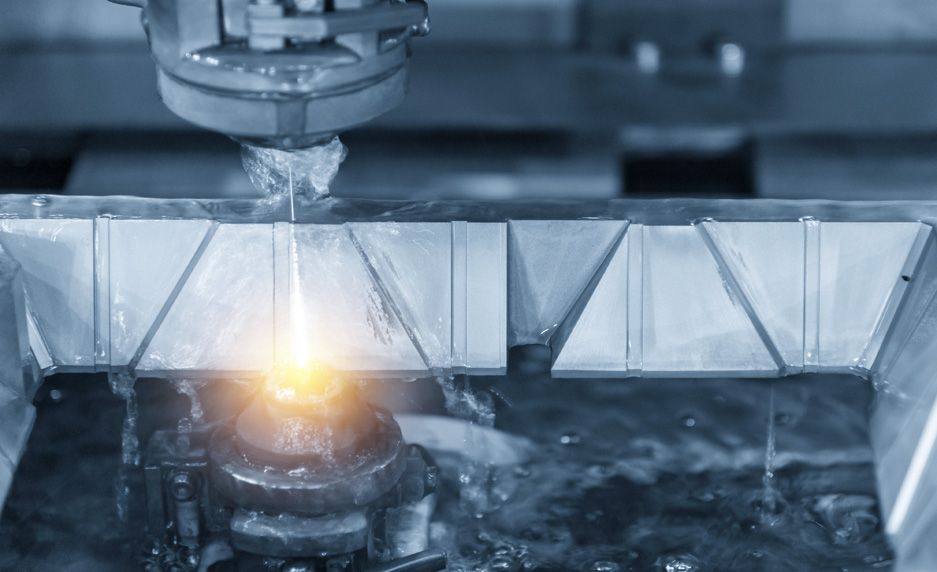

Wire Electrical Discharge Machining

This is also known as wire-cut EDM, wire cutting, EDN cutting, EDM wire cutting, wire burning, wire erosion, wire cut electric discharge machining, and ‘cheese-cutter’ EDM.

Wire electrical discharge machining (WEDM) uses a metallic wire to cut and/or shape work pieces, which are often a conductive material with a thin electrode wire that follow a precisely programmed path.

During the wire cutting process, there is no direct contact between the wire and the workpieces. This allows for machining without distortion in the path of the wire or the shape of the material. The wire is very rapidly charged to a desired voltage, and also surrounded by deionized water. When the voltage reaches the correct level, a spark jumps the gap and melts a portion of the work piece. Deionized water cools and flushes small particles from this gap.

EDM Cutting Applications

- Used with thick parts requiring good finishes and accuracies

- Delicate or small work pieces that can be damaged during conventional machining or other techniques

- Larger parts requiring accurate tolerances

- Narrow slots and complex shapes

- Delicate, hard, expensive, exotic or weak materials