Transfer Dies

What Is Transfer Die Stamping?

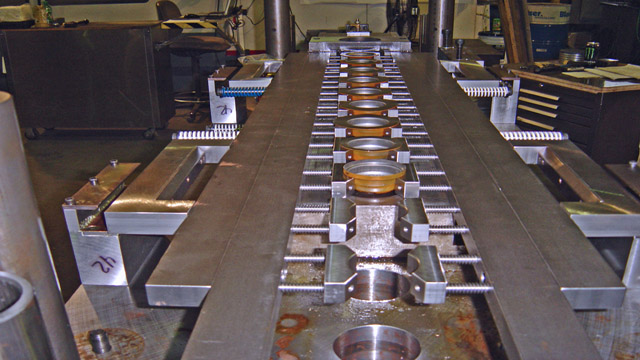

Transfer Die Stamping is similar to a progressive die, but the part is transferred from station to station by a mechanical system. It’s mainly used where the part has to be free from the strip to allow operations performed in a free state. A transfer die can be a single die or a numbers of dies or machines, arrange in a row to form a production line.

Transfer dies are usually used for high volume, medium sized parts, such as: pillars, control arms, cowl panels, and heat shields. Because it’s flexible and cost effective, it can be used to create a variety of metal parts and products.

Transfer die stamping is a method that produces a component by passing a blank through a series of dies installed across a set of stations operated by a single press. The blank is first separated from the larger metal strip, so it can be freely transferred. Then it’s transferred from one station to the next by a mechanical transport system until it is completely formed. This eliminates the need for manual transfer and reduces the risk of misalignment or mishandling. Since transfer operations occur simultaneously, the production line doesn’t get backed up.

Additionally, transfer presses can hold tooling for threading, knurling, piercing, chamfering, and other forming processes. This can enables manufacturers to combine other secondary operations into the stamping process.

Transfer Die Stamping vs. Progressive Die Stamping

Transfer die stamping is similar to progressive die stamping. Both use multi-station dies to turn a blank into a finished component. The main difference between them is that transfer die stamping removes the blank from the metal strip at the beginning of the stamping process. Progressive die stamping removes the blank from the metal strip at the end of the stamping process. This difference makes the two stamping methods suitable for different parts and products. Transfer die stamping is can be better suited for producing larger and more complex components. Progressive die stamping can be better suited for producing smaller and simpler components in high volumes.

Benefits of Transfer Die Stamping

Transfer die stamping offers a number of benefits compared to other manufacturing processes.

- It can create parts faster than stamping processes with manual transfer operations.

- It can eliminate the need for separate post-stamping operations, such as knurling and threading.

- It can create more complex and intricate components, since the part is separated from the metal strip at the beginning of the process.